Foam Technologies

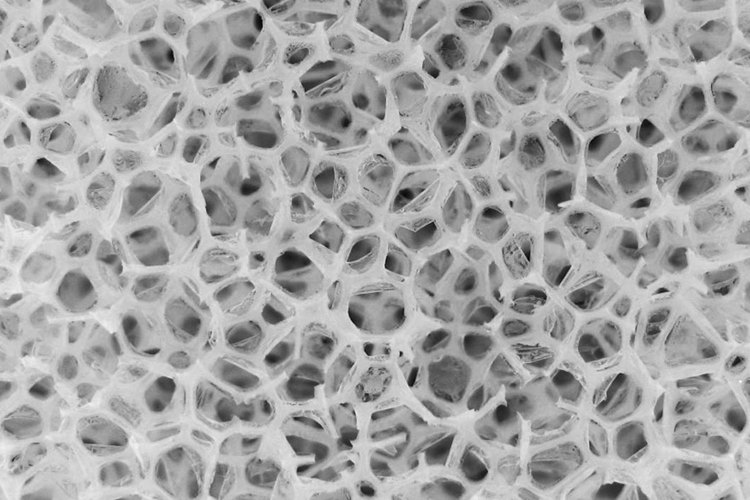

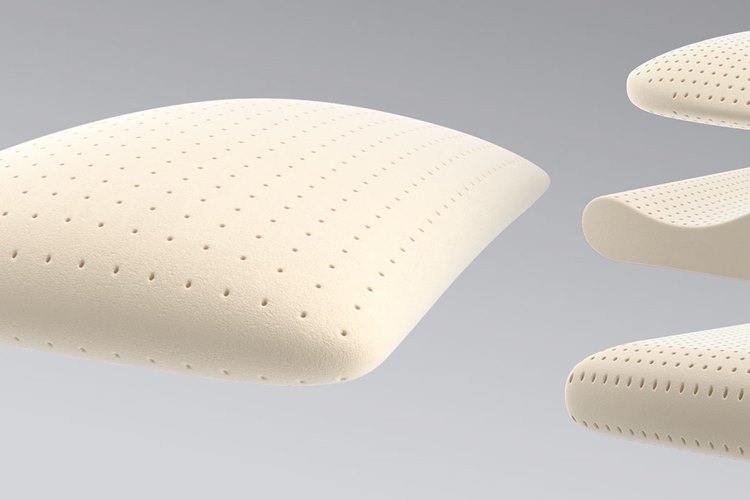

Peterson Chemical Technology develops advanced polyols, additives, and foam types for the polyurethane foam industry, with an emphasis on viscoelastic foam for bedding and top-of-bed applications. We provide our customers with unique and innovative solutions that open new opportunities in the marketplace. Learn more about our technologies below.